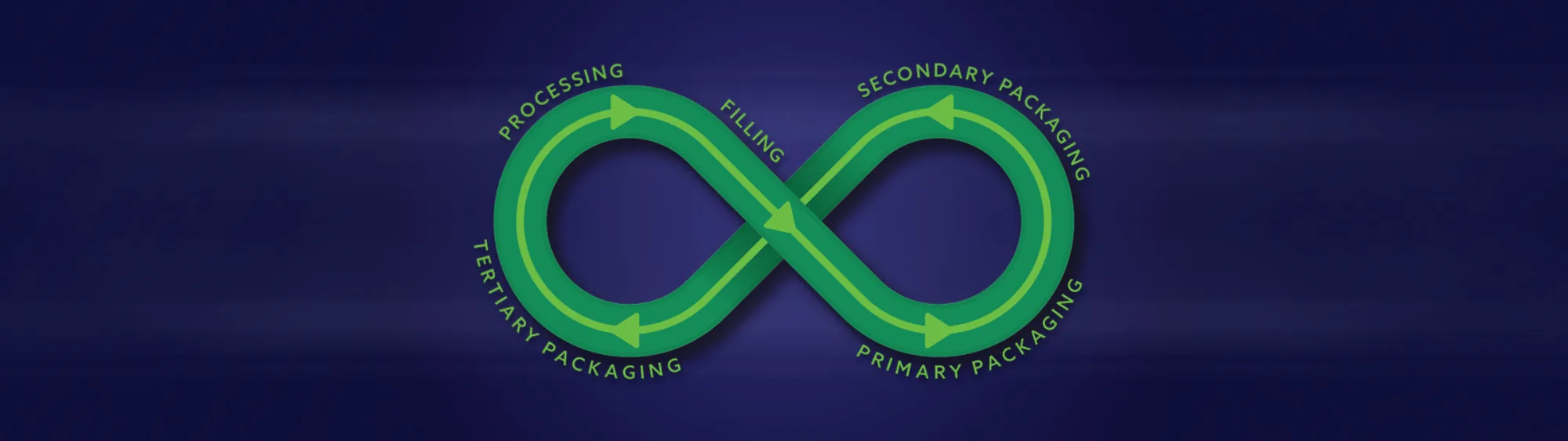

Performance at Every Point of Your Production Line

• PROCESSING

• FILLING

• PRIMARY PACKAGING

• SECONDARY PACKAGING

• TERTIARY PACKAGING

With a near-limitless array of solutions, ProMach has the expertise and know-how to meet nearly any production line challenges. We’re a flexible partner that can adapt to your unique needs.

As your partner, we understand and adapt to your unique needs for processing and packaging, ensuring optimal performance and efficiency in your operations. And our commitment to innovation and customer satisfaction sets us apart, making us your go-to choice for comprehensive solutions.

PROCESSING

SYSTEMS

Transforming raw ingredients into finished goods that are ready to package using sanitary design principles, engineered to order systems, and installation services for facilities at production scale of all sizes.

STANDALONE

PACKAGING MACHINES

Primary packaging solutions for the product on the shelf, secondary packaging solutions to get products safely to the shelf, and labeling, coding, and tertiary packaging solutions to track products throughout their journey.

CELLULAR

INTEGRATED SYSTEMS

Integrating and modifying multiple machine centers together into more efficient combination systems at the front, middle, or end of new or existing production lines to meet the challenges of ever-changing consumer needs and customer specifications.

COMPLETE

TURNKEY LINES

Offering complete production line design, engineering services, and integration to plan, source, and start up large projects, delivering best-in-class turnkey processing and packaging lines with single source responsibility.

Processing is the cornerstone of product development and packaging, creating the very essence of what reaches the market.

Processing plays a pivotal role in delivering products that resonate with dedicated consumer loyalty. When executed with precision and consistency, it ensures that every element, from ingredient blending to final storage, meets exacting standards, resulting in a finished product that not only meets but often exceeds customer expectations.

As a single-source provider of turnkey processing and packaging lines, ProMach is committed to enhancing the efficiency and cost-effectiveness of businesses, regardless of their size. Specializing in food, liquid food, and beverages, our global team of technical application and engineering experts thrives on managing the most demanding production environments.

Customer Testimonial

See and hear how Milo’s Tea has relied on Statco-DSI for pasteurization and processing expertise for 20+ years, enabling the business to grow consistently, year over year.

Filling is a critical juncture in the packaging process, where precision and efficiency converge to preserve the quality and freshness of your product.

At ProMach, we elevate the filling stage beyond mere functionality, balancing accuracy with speed.

Our filling technologies cater to a broad spectrum of products and viscosities, ensuring each item is filled to the precise specifications with consistency, and meeting strict quality standards. This attention to detail not only safeguards product integrity but also maximizes production throughput, enhancing overall operational efficiency.

Customer Testimonial

See and hear how High West Distillery upgraded from manual filling to running 50 bottles per minute with the help of Fogg, allowing them to scale their portfolio and increase production output.

Primary packaging is the first line of engagement between your product and the consumer, representing the brand's promise and quality.

It is the critical phase where protection meets aesthetics, ensuring the product's integrity while attracting consumer interest at first glance.

Our expertise in primary packaging ensures that each product is not only securely contained but also presented in a way that enhances brand recognition and consumer trust. From concept to execution, our team of experts ensures seamless, efficient, and cost-effective packaging solutions that elevate your product's market presence. With ProMach as your partner, you can expect nothing less than packaging excellence, designed to exceed your production goals.

Customer Testimonial

See and hear how Hudson Valley turned to Ossid to help their poultry packaging stand out on grocery shelves by providing reliable and flexible tray wrapping solutions.

ProMach excels in servicing the secondary packaging phase of the production line, a crucial step in the packaging journey.

This stage, involving key processes such as cartoning, bundling, and vital aspects of labeling, coding, and marking, is essential for ensuring products are packaged securely. In this phase, ProMach's approach is centered around precision, adaptability, and innovation.

Recognizing the diverse requirements of different products and industries, ProMach offers customized solutions that are both flexible and scalable. ProMach's expertise in secondary packaging extends to accommodating a wide array of packaging formats and sizes, ensuring that your unique product specifications are met with the highest standards. With a focus on integrating seamlessly into existing production lines and adapting to evolving market demands, ProMach’s emphasis is on you helping you achieve heightened productivity and maintain a competitive edge in your market.

Customer Testimonial

See and hear how ID Technology helps Mrs. Renfro’s keep up with changes in retail shipping requirements, upgrading their system to follow mandates while increasing labeling speeds with fewer changeovers.

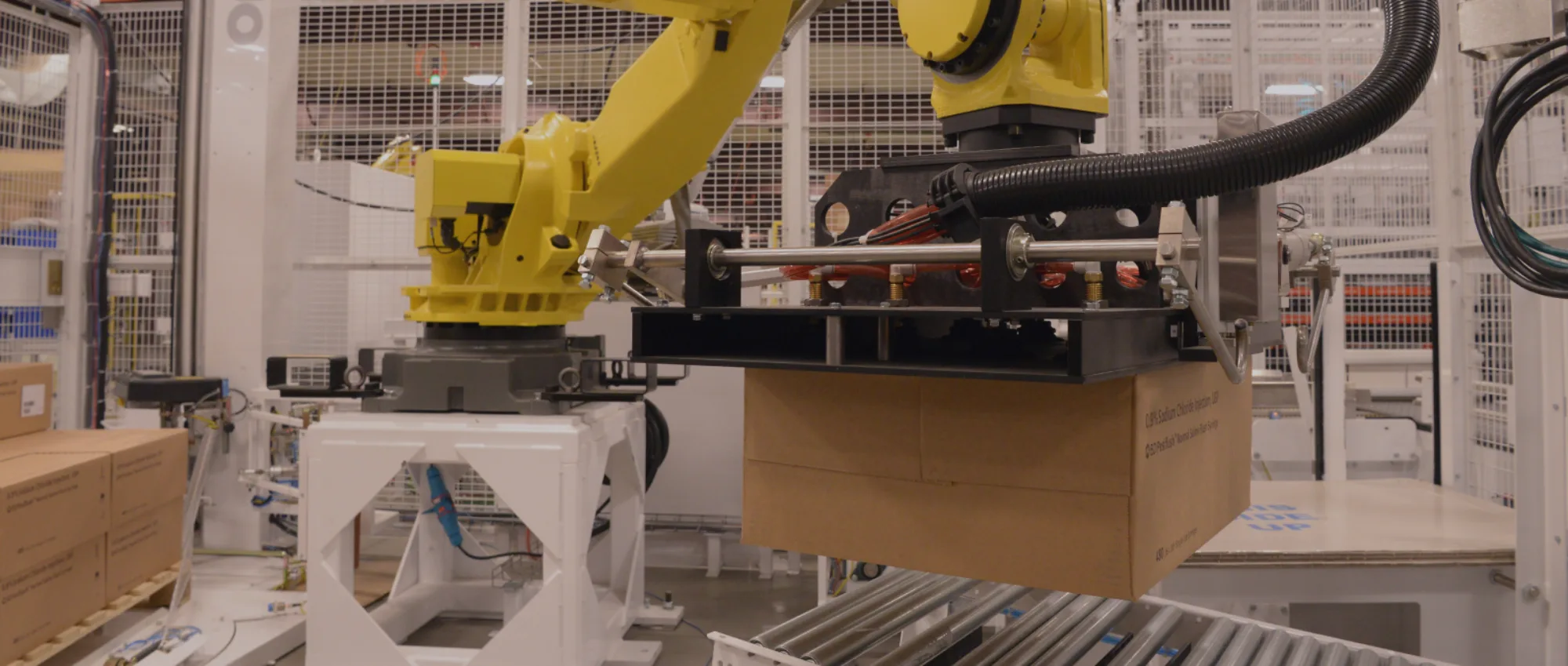

Tertiary packaging, the final touch point in the journey from production line to consumer, is an essential stage in the packaging line that ensures product is delivered safely and securely.

This phase, encompassing tasks such as palletizing, wrapping, and labeling is integral in ensuring products reach consumers in pristine condition.

Recognizing the inherent risks associated with manual handling in this segment, ProMach places a strong emphasis on safety. By integrating advanced automation solutions, including sophisticated robotics, ProMach transforms this traditionally labor-intensive and potentially hazardous process into a seamless, efficient operation. This shift not only enhances the safety of the workforce but also elevates operational efficiency. Whether it’s addressing entry-level needs or catering to high-speed, large-scale operations, ProMach’s diverse range of solutions ensures optimal performance, helping you achieve your production goals with greater efficacy and value.

Customer Testimonial

See and hear how Snak King optimized efficiency in throughput and labor by trusting Quest and Brenton for robotics and end of line systems to automate production and maintain their competitive edge.