Complete Processing & Packaging Solutions for the Craft Beer and Brewing Industry

ProMach supports the brewing process with a brewhouse suite of solutions for malting, milling, mashing, lautering, boiling, fermenting, conditioning, and filtering—matched by a lineup of superior primary and secondary packaging solutions to provide brewers everything necessary to get the beer flowing and packaged into bottles and cans for store shelves both near and afar.

CRAFT BEER CAPABILITIES (click on any for more detail)

TAILORED SOLUTIONS FOR THE CRAFT BEER INDUSTRY

Click to view our video showcasing ProMach's processing and packaging solutions for the craft beer and brewing industry.

CUSTOMER TESTIMONIAL

When Narragansett Brewing set to revitalize their brewery operation, they called TechniBlend and ProBrew to help with custom brewing technology. The teams provided customized cellar and fermentation tanks for beer processing to help expand their product offerings and grow their business nationwide.

CUSTOMER TESTIMONIAL

When Flying Embers Brewery wanted to grow their business from a small, artisanal brand to a global manufacturer, they partnered with TechniBlend and ProBrew to help deliver best in class brewing technology. The result is a canning line running 200 cans per minute with national distribution.

CRAFT BEER SOLUTIONS OVERVIEW

The information you need, when you need it—download our brochures for instant access to a wealth of valuable resources. From product guides to market reports, our brochures provide comprehensive information that will help you stay ahead of the competition and make strategic business decisions.

At the heart of all good beers and seltzers is a proven recipe and the use of quality ingredients. Following close behind is the build-out of a reliable production system that allows you to achieve process consistency at increasing volumes. Whether your brewing process needs 2 vessels, 4 vessels, or more, we account for and design brewhouses at every scale.

CARBONATED FILLING

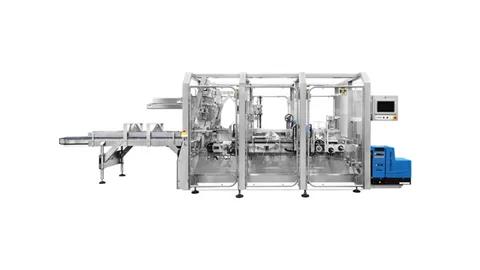

The entire line of beer filling systems is designed around maintaining the product's integrity while delivering best-in-class levels of production efficiency, throughput, reliability, and simplicity. We offer systems able to achieve precise and consistent filling volumes in multiple can sizes with built-in automatic pressure control that guarantees carbonation levels and saturation pressures are always achieved for optimal product stability and quality

PACKAGING OF EVERY KIND

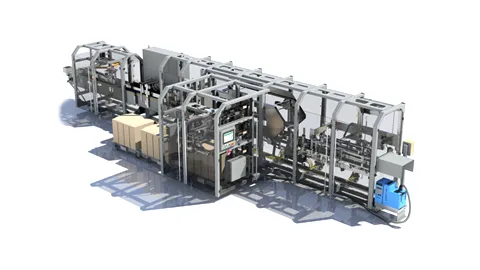

Packaging begins the moment a can is filled, and seamless integration from that point helps to keep the line moving efficiently. However, how it gets packaged depends on the level of automation desired and the type of packaging being used. Our available packaging options have breweries covered no matter the need or situation and support everything on the packaging line all the way through pallet wrapping.

LABELS & BEER CARRIERS

The packaging materials used in or with the packaging equipment also play an important role, as these are the materials that end up being part of the final product presentation. We are a reliable supplier of various labels and shrink sleeve films, as well as plastic can carriers.

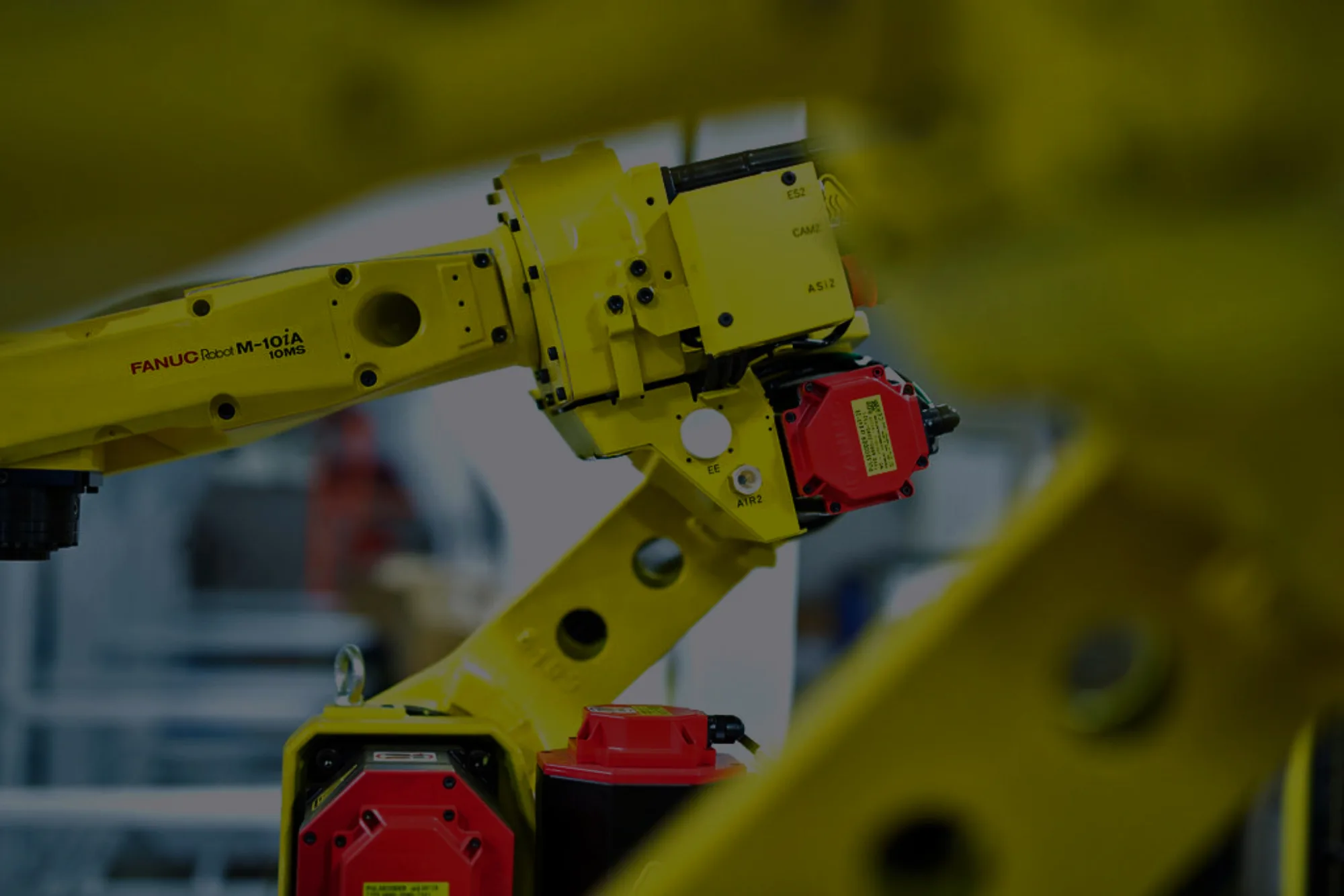

END OF LINE SOLUTIONS

Bundle it, pack it, seal it, palletize it, wrap it, and go. ProMach offers customers a single source for all their robotic and end of line packaging needs, from standalone applications to complex packaging systems for the craft beer industry.