Innovation Meets Excellence

ProMach maintains a continuous and intentional focus for developing and delivering new solutions that are at the forefront of packaging innovation. Browse our latest processing and packaging solutions, brought to you by our best-in-class product brands.

BROWSE LATEST INNOVATIONS BY BUSINESS LINE

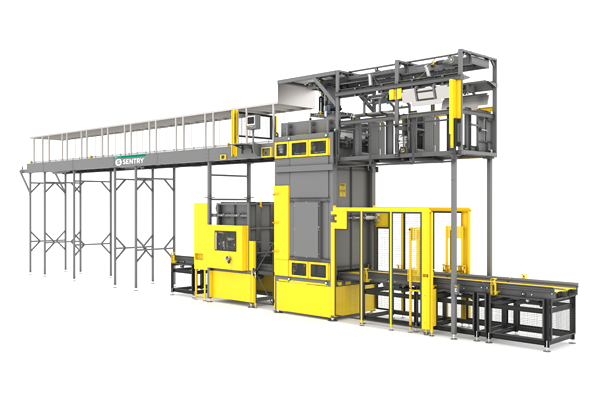

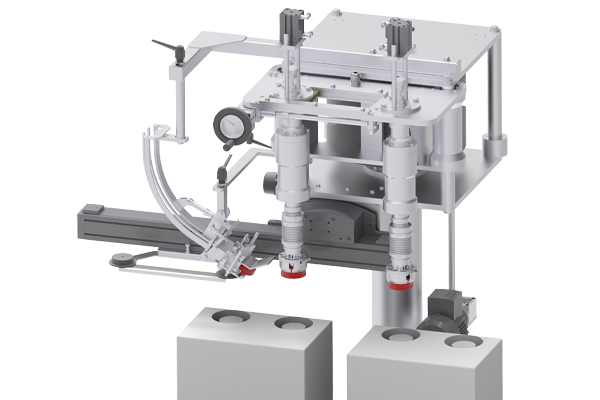

HIGH SPEED DEPALLETIZER

Experience unparalleled efficiency and performance with the industry's leading solution for bulk can depalletizing.

- Available in four models with speeds ranging from 2,300 to 3,500 cans per minute.

- Engineered for maximum throughput with cutting-edge innovation.

- Specifically designed for efficient and reliable can handling.

- Optimizes production lines with high-rate, consistent performance.

- Features state-of-the-art dunnage and tier sheet handling for unmatched speed and efficiency.

0625

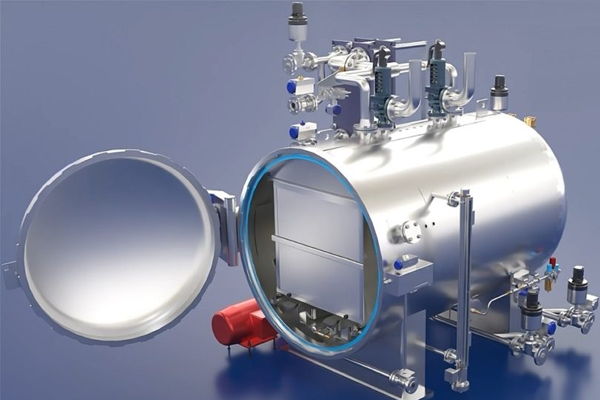

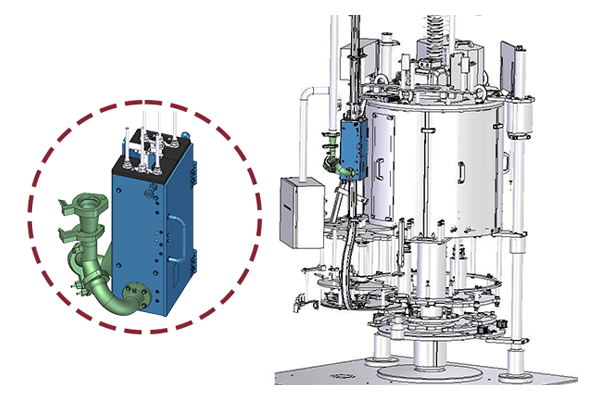

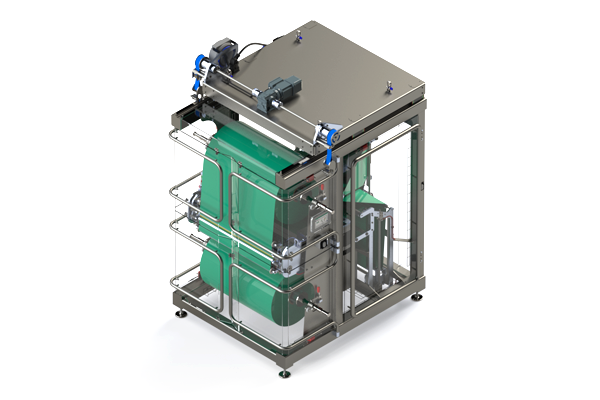

IMMERSAFLOW® RETORT PROCESS SOLUTION

Innovative design pushes water through the inside of the solid sidewall basket and around all the containers, eliminating the need for a flooded vessel.

- Ultimate temperature uniformity in heating and cooling.

- Shorter come-up and cooling times.

- Improved product quality (color, texture, taste).

- Up to 50% more load capacity with flexible containers (i.e.: pouches).

- Required number of retorts is potentially reduced, thus reducing footprint and maintenance requirements.

- Significant reduction in energy and water usage.

0925

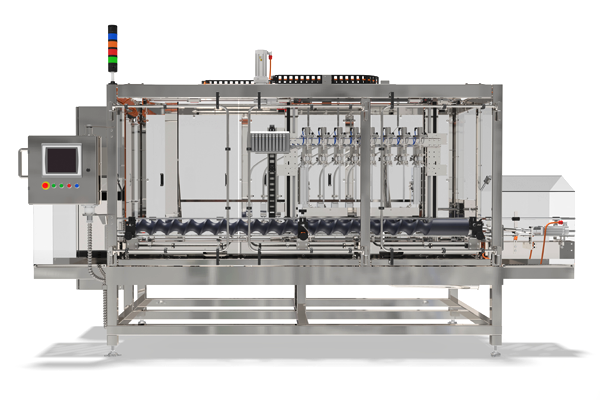

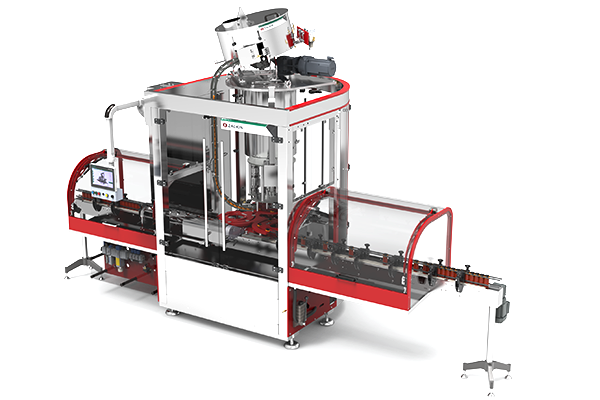

INTELLI-FIL C SERIES

Industry-leading precise filling accuracy for retail-sized containers in high SKU production environments.

- High accuracy achieved with mag or mass meters eliminates product giveaway.

- Delivering speeds ranging from 20-600 CPM in a reduced footprint.

- Fewer wear parts than piston filling systems.

- Changeover time is greatly reduced by utilizing only a feed screw for container handling.

- Additional capabilities include: no bottle – no fill, top or bottom-up filling, Class I Division 1 XP arrangement, corrosive product arrangement.

0625

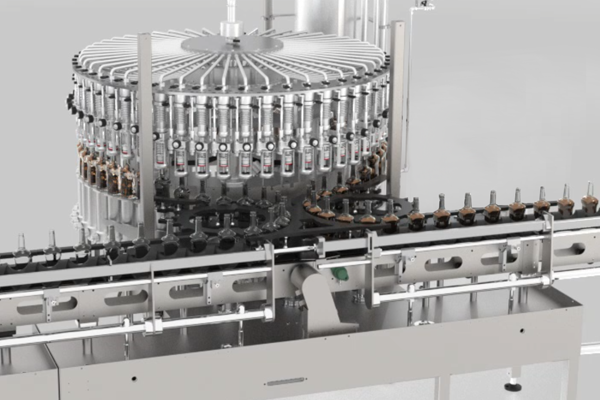

PF SERIES PRESSURE FILLER

- Vacuum-less, minimized aeration process ensures no proof loss in spirits filling.

- 0-100% fluid recirculation capable valves for hot fill temperature control—online in production mode or offline in idle mode.

- Increased bottle fill and production speeds, consistent fill heights in a cleaner filler environment with reduced footprint.

- Automated CIP/SIP cleanability.

- Precision predictive pumping technology.

0625

OMNI-IR ™ AUTOMATED LINEAR UNSCRAMBLER

Transforming manufacturing efficiency with advanced features, offering exceptional versatility and dependable performance.

- Capable of unscrambling PET, HDPE, PP, PS, and PVC plastic containers at speeds of 250 to 650 CPM.

- Supports up to 25 formats with automatic changeovers in under 5 minutes.

- Improved ergonomics with taller access on the operator side for easier operation and maintenance.

- Achieves significant cost savings through the use of efficient servo motors and the elimination of AC motors.

- Compact footprint enhances floor space use by up to 15%.

0625

VERSASORT ™ ROBOTIC UNSCRAMBLING & ORIENTING SYSTEM

Container unscrambling with a cutting-edge transfer system and versatile features.

- One of the fastest throughputs per robot unit in the market, reaching speeds up to 340 CPM.

- Patent-pending transfer system uses suction and air to protect containers from crushing, scuffing, or scratching.

- Handles containers from 10mL to 9.5L with the same tooling, reducing changeover frequency by up to 25%.

- Features an integrated hopper, comes puck integration-ready, with a built-in BAO orienting system.

0625

FTM-300 TANDEM CAPPER

Adjustable pitch tandem capping machine.

- Versatility in accommodating formats such as JIBs and Twin Packs.

- Adjustable pitch for capping heads.

- Quick and consistent mechanical adjustments.

- Servo driven cap distribution to adjust stroke and positions.

- Rapid changeover capability for different pitch settings.

0625

OPPTI.PURE – Microparticle Extraction

Zalkin’s-patented system achieves up to 99.9% extraction of residual microparticles from caps just before the capping area.

- Maximum Efficiency: Delivers up to 3 log reduction in microparticles.

- Universal Application: Suitable for all production outputs and market segments.

- Comprehensive Expertise: Covers the entire process from bulk handling to capping.

- Continuous Performance Monitoring: Ensures consistent system efficiency.

- Wide Compatibility: Works seamlessly with both Zalkin and Non-Zalkin /OEM equipment.

0925

OPPTI.CAP MH Capper

The cornerstone of Zalkin's lifecycle analysis and eco-design approach.

- Low Energy Consumption: Achieved through servo technology and the latest air-free cap orienter generation.

- Enhanced Ergonomics: Features a user-friendly HMI, great accessibility and POKA YOKE design for fast changeovers.

- Scalable Design: Easily adaptable throughout its lifecycle with modular components and upgrades.

- Seamless Integration: Equipped with OMAC Pack ML communication systems, allowing easy connectivity with upstream and downstream equipment for smooth integration into production lines.

0925

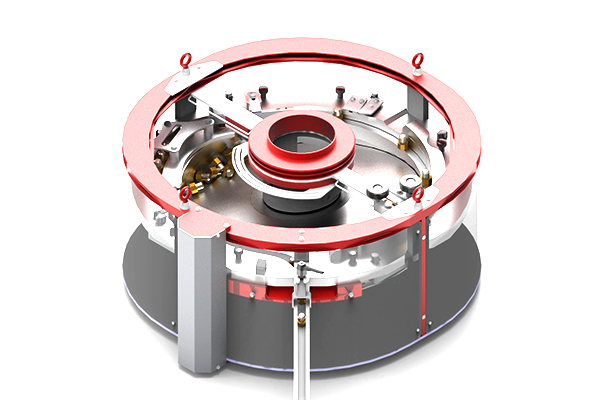

Pro Select ECOTWIN ET800

Zalkin's new Pro Select ECOTWIN is an airless*, centrifugal, double-disc rotary orienter designed to significantly cut energy costs.

- Low Energy Consumption: Reduces overall energy expenses.

- Smooth and Silent Cap Handling: Ensures product integrity throughout the process.

- Optimized Design: Fewer format parts and easy access to improve operational efficiency and maintenance management.

- Versatile Application: Suitable for all market segments.

- Capacity: Handles up to 40,000 caps per hour for flat caps with a diameter <60 mm and height <25 mm.

* Dependent on cap design

0925

MVC-250

Groundbreaking continuous box-motion bagger designed for high-performance packaging in tight/short spaces.

- Equipped with a cutting-edge servo system for precision motion control.

- Compact design (62” height) perfect for low ceilings or confined spaces.

- Achieves speeds up to 200 cycles per minute without sacrificing performance.

- Continuous motion jaw system allows for maximum speed with optimal seal dwell time for diverse film types.

- Integrated with a Yamato scale, CL&D film, and ID Technology printer for a complete packaging solution.

0625

FL AUTOSPLICER PRO

Stop losing money on manual roll splicing and automate your vertical and horizontal pouch packaging machines with the FL AutoSplicer Pro.

- Boost efficiency by up to 10%.

- Drastically cut material consumption.

- Increase output with reliable 24/7 operation.

- Reduce labor costs and enhance operator safety.

- Quick setup with ROI in just 3-6 months.

0625

TELESCOPE

The Future of Labeling: AI-Powered Machine Diagnostics.

- Advanced labeler performance metrics for real-time insights.

- Fully customizable KPIs tailored to your production needs.

- Proactive detection of inefficiencies and bottlenecks.

- Business-specific recommendations to boost productivity.

0625

L-MAX DIGITAL LABEL PRINTER

Designed for performance and sustainability, offering high-speed label printing for inline, rotary, and pressure-sensitive applications on demand.

- Digital on-demand entire label printing.

- Single Color, 4-Color, and SPOT UV capable.

- High-speed – Up to 600 labels per minute.

- Cost-efficient – zero overproduction and minimal waste.

- Integrated web handling for variable labeling applications.

0625

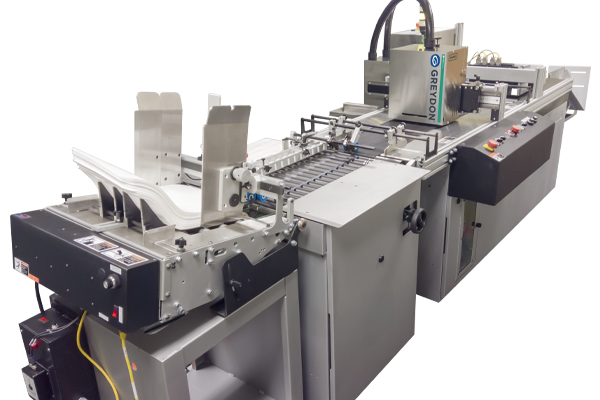

VARIIS DIGITAL PRINTER

Digital printer designed to be integrated with carton and card feeders for full-material printing and late-stage customization.

- High-resolution digital on-demand printing.

- Single Color, 4-Color, and SPOT UV capable.

- Designed for standalone off-line printing with full integration capabilities.

- High-speed – Up to 450 ft/min printing capacity.

- Eliminates the need to source and manage pre-printed items, allowing for lean manufacturing.

0625

265 CARBONFLEX™ PRINTER APPLICATOR

Combining precision and performance with flexibility, the 265 CarbonFlex™ high-speed printer applicator is the perfect solution for labeling cases, trays, shrink-wrapped products, or pallets.

- High-speed print and apply labeling for greater efficiency.

- Single and multiple panel labeling, even with imperfect product handling.

- A patented servo-controlled flexible applicator provides precision labeling.

- All-electric design reduces operating costs – no compressed air required.

- Multiple orientations for maximizing label capacity.

0625

RL1000

Palletizes full layers swiftly and smoothly, no vacuum end of arm tool required.

- Servo-operated rotary tool outperforms vacuum pick and rollers.

- Palletizes layers of open or sealed cases.

- Extra layer accumulation results in rates up to 6 layers/min.

- Handles full layers up to 600 lbs. and supports them from beneath.

- Eight standard layouts allow configuration to each automation need.

0625

EZ20

Rennco’s gateway to automation.

- All Electric — 110 V.

- Up to 25 bags/min.

- Uses centerfolded material—no pre-made bags.

- Small footprint and versatile.

0625

BEL 5150AA Semi-Automatic Form, Pack & Seal with Auto Adjust System

A compact, high-performance form, pack, and seal solution designed for ultimate efficiency. With its innovative automatic case size changeover, this all-in-one system enhances productivity while minimizing downtime.

- Seamlessly switch between case sizes in seconds via HMI touchscreen.

- Achieve speeds of up to 15 boxes per minute, maximizing throughput without compromising quality.

- Simplify operations with a single push of a button, reducing reliance on operator expertise and cutting down on training time.

- Safe, two-handed case packing that securely forms and holds each case in place.

- Optimize plant floor space via compact design for a perfect fit for almost any application.

0825

DEVICE STABILIZERS

Developed to optimize the labeling of autoinjector devices on rotary labelers.

- Ensures axial force and torque limits of device cap are not exceeded.

- Utilizes the windows molded into the outside surface of the pen device.

- Eliminates the need for expensive active pucks.

0625

TF1e BLISTER MACHINE FOR SUSTAINABLE MATERIALS

This new technology allows for sustainable materials to run successfully every time.

- Servo driven, auto-adjusting stations compensate for sustainable material inconsistencies.

- Laser feedback tracks position of blister material.

- Enhanced heating of materials improves forming and sealing.

0625

UNISPLICE™ LABEL SPLICING SYSTEM

This automatic splicer cuts and seamlessly joins the expiring roll to the new roll.

- Achieve zero downtime on your production line.

- Uninterrupted and continuous label application.

- Detects when label roll needs replacing.

- Process maintains productivity and efficiency in the label applicators.